Are you looking for a round bale wrapper for sale? You may be confused in choosing the bale wrapper that best suits your budget and the condition of your forage or hay.

However, your confusion can be resolved a little by having information about what a round bale wrapper is, how to treat hay bales, and how to remove a round bale wrapper when needed. If you already know all the things about a round bale wrapper, then you will be able to easily choose the best round bale wrapper you need.

Contents

What Is Round Bale Wrapper?

Do you often see videos posted by a company website that sells round bale wrapper? What interesting things do you see first? Wasn’t a medium-sized tractor-like machine that spun rolls of hay several times to be wrapped in tight white plastic? Is it exciting watching the video, isn’t it?

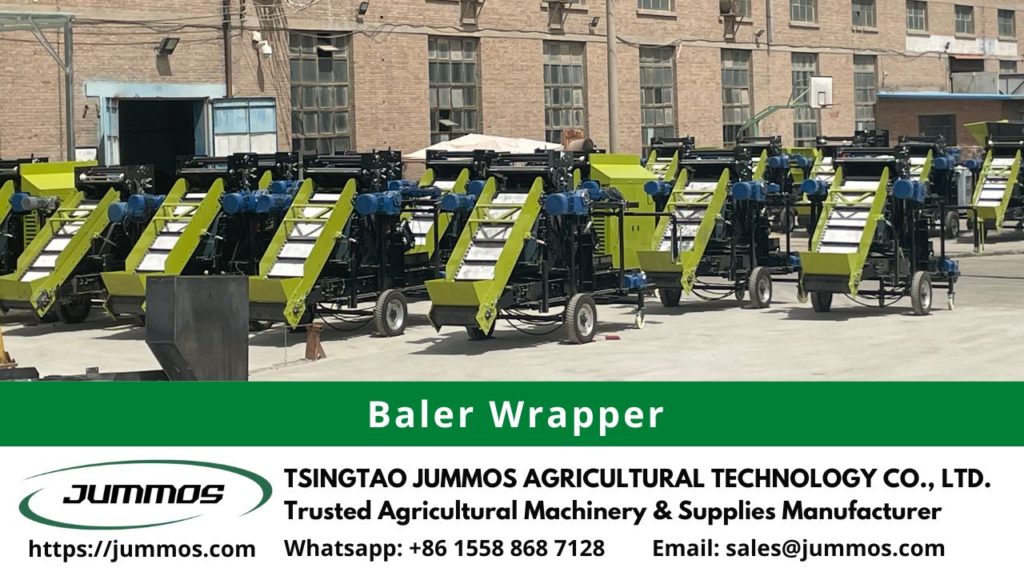

You will enjoy such views more often in the meadow in your farm area when you already have a round bale wrapper. You need to have that round bale wrapper to help you pack the feed for stock months ahead. It is because your cattle deserve more good feed than only dry hay. A round bale wrapper will wrap the forage or hay so that it has higher nutrition than dry hay. Get one or more round bale wrapper from a trusted company now.

Estimate The Price of Round Bale Wrapper for Sale

Before you decide to buy one round bale wrapper for sale product from the internet, you need to know the approximate price of bale wrapper per roll, how much you have to pay for wrapping all the hay bales in your pasture, and the price of bale wrapper machine.

If you’re lucky, you may get a promo or discount price when you click on one of the round bale wrappers for sale website links. But, don’t you need to know the normal price for the round bale wrapper for sale for the next purchase when there are no promos?

However, you can estimate the price of the round bale wrapper for sale by looking at its color. There is a round bale wrapper for sale website that points out that color plays a role in pricing. Some suppliers say that color doesn’t affect the price. You may find yourself later in a shop that sells bale wrapping products in selected colors such as white, green, pink, and black. Most white, pink, and green bale wrappers cost slightly more than standard black wrappers. The standard black wrap is what most breeders use to wrap hay or silage. Meanwhile, a white wrap is used to prevent excessive sun heat from hitting the silage.

Furthermore, you can also find out the estimated price of round bale wrapper for sale machine by asking directly to the agent on duty on the website of the company that produces round bale wrapper machines such as agents at www.jummos.com.

Round Bale Wrapper Machine

The use of a bale wrapper machine makes it very easy for users to form round solid bales that comply with the TMR mixer standard. Why round? This adapts the form of a mixer machine that is mostly used in farms and the round shape of the bale wrapper makes it easier for workers to remove the bales when they need animal feed in difficult times such as drought. This solid bale will then be made into silage bale with the same shape as the original to increase the selling value of each ball and feed needs moisture to keep it together. The plastic wrap is often used in high humidity blades.

The farms that will become your business partners will be greatly facilitated by the bales of silage that you make because the animal feed can be easily be put into a TMR mixer to chop animal feed so the cattle are easy to digest. Moreover, the nutritional value of forage or silage wrapped in a round bale wrapper will increase due to the fermentation process.

For other round bale wrapper for sale models that match your interests, please contact us. Our company also sells other products related to bale wrapper. You can order a film wrapper with the color you wish and without logo, so you can make your animal husbandry logo on it.

Types of Bale Wrapper

You need to focus on taking things into account before buying it, including purchasing a round bale wrapper for sale. Manufacturers provide various types of wrappers with many attractive features. All of this is an effort to protect feed quality. Not all of the feed you have today will be consumed immediately, it is crucial to keep it at optimal quality and nutritionally stable. Small and large-scale farmers need to pay attention to this so that livestock can enjoy high-quality feed all year round.

The features of wrapper machines are also diverse, they work with efficiency, and flexibility and maintain wrapping quality. The types of round bale wrappers for sale also vary, such as swing arm, platform, in line, single bale wrapper, and spear bale wrappers. The following is an explanation and function of each wrapper.

Swing arm wrap

This wrapper has an open roller feature, its function is to pick up the bale, and the tools will close and start wrapping the bale. The movement of the plastic roll is like a swinging arm to surround the bale.

Platform wrapper

A wrapper that works automatically and quickly rotates the input (bale) and then inserts it into the plastic from the roll provider.

Bale spear wrapping

The advantage of this wrapper is that the system works to wrap the bales continuously, so it saves plastic because you don’t need plastic for the ends of each bale. Usually, this type of wrapper uses a hydraulic motor.

In-line wrapping

This machine is like a parallel wrapper that functions to place bales from end to end in sequence. At the same time, it removed the plastic from the rollers surrounding the bales.

Single bale wrapper

It is one of the most sophisticated types of machines because it can work optimally in wrapping large round or square bale rolls. You can control this machine manually or by computer.

From the list above, it turns out that there are other types of round bale wrappers for sale. However, currently, the most common type in bale wrapping operations is the in-line wrapper. Why? Because this type works efficiently, is easy to operate, and can reduce the need for plastic. In line with technological developments, there are now also types of wrappers whose operation does not have to be done on-site. You can control it remotely. It requires little effort and human resources.