Silage is arguably the most popular kind of livestock feed these days, and it’s for many good reasons. Silage is essentially a bunch of plant parts that have been put through fermentative processes. This is done because most livestock animals are not capable of digesting the cellulose content of the plant materials.

Ruminants process their food by fermenting it inside their first chamber of four stomachs, the rumen. Fermentation inside this stomach helps break the plants down. The partially digested food is then regurgitated back into the mouth for a second chewing. Following this, the food is pushed down to the subsequent stomach chambers before entering the intestines for further absorption of nutritional components.

If silage is the most popular feed variety, round silage is perhaps the most common baling shape around, courtesy of the working of a silage round baler. The reason why round is the preferred shape for baling silage can be attributed to convenience.

Round silage can be produced manually simply by rolling the prepared materials. The bulk can be left out in the open or transported to a barn for safe storage. Round bales can be taken out of the barn whenever needed simply by pulling one batch and rolling it to the feeding site. Still, as easy as it may be to form a round bale by hand, productivity can be improved further by using a silage round baler.

Contents

The Functionality of Silage Round Balers

A silage round baler works to significantly expedite the entire process, so less time will be invested in making bales. You start by preparing the freshly harvested crops and then putting the entire crops into a chamber on the baler. The augers and other supporting components chop and cut the materials into smaller chunks. The movement of the baler causes the entire materials to form a cylindrical shape.

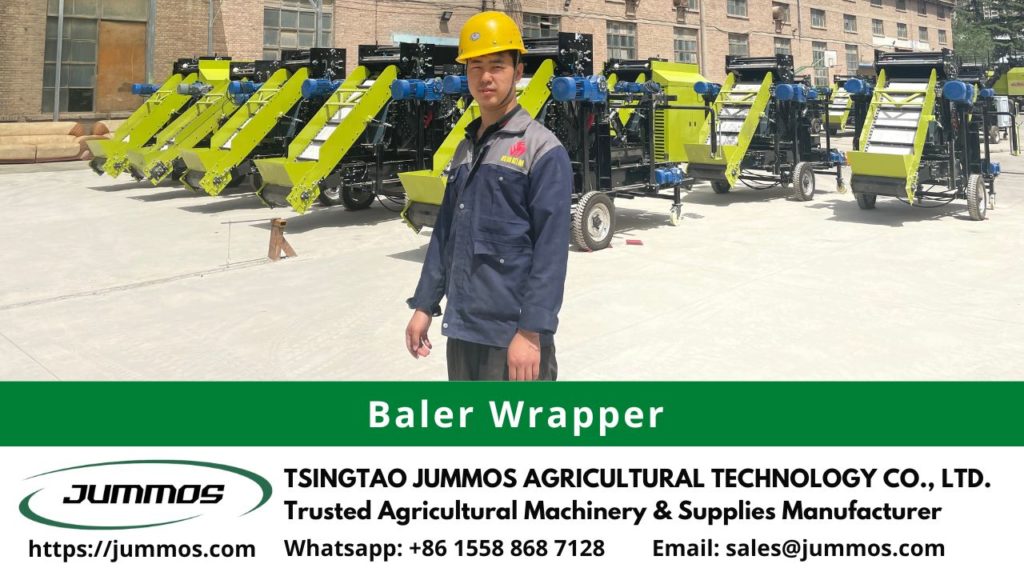

Once the process completes, the machine ties up the resulting bale with either twine or netting. The end product is ejected through the other end of the baler for you to collect and arrange. Though considered already complete, the produced bales can be further treated by wrapping them in special plastic packaging to protect them from exposure to the elements.

A silage round baler is also available in its mini variant. Thanks to its small build, a mini round baler is a perfect addition to a small-sized farm. Their smaller footprint will not take up too much space when stored. It will also be a lot easier for the farmer to move it around according to their preferences.

Limitations of Silage Round Balers for Livestock Feed Businesses

A common disadvantage of using a silage round baler is its capacity. A round baler is limited in its ability to continuously produce bales. It needs to stop now and again to provide chances to tie a bale up. As such, it takes time to complete a cycle, and this may affect the way you can start feeding your animals and move on to the next job on the list. This also means that a baler of this kind is not suitable when you consider starting a livestock feed business. Customers may come fast while you are not able to keep up with the increasing demands from clients.

The Role of High-Quality Wrappers in Fermentation

A high-quality wrapper is a good companion for a silage round baler. Silage is produced using wet materials. Wrapping these materials in durable film sheeting will promote a desirable environment that is perfect for a fermentation process to take place. The wrapper also offers an airtight sealing property that keeps moisture and oxygen from getting inside. Allowing both components to get mixed in the prepared plant materials will only lead to rot, and the silage wouldn’t be viable if it rots.

Getting suitable film sheeting for you to use with a silage round baler is no longer a daunting task with us at Jummos. Our silage wrapper is proven of the highest quality that clients and customers are giving positive feedback. We also offer overseas shipping, so no matter where you are, you can always rely on our dependable products. Please visit our official website for further information about pricing and the products in general.