Every seasoned farmer knows the sinking feeling. Watching weeks of hard work and investment literally rot away in the field. However, the round bale wrapping solutions will make it easier for you to go about your chores. It’s not just about keeping feed dry. It’s about preserving nutritional value, saving money, and most importantly, saving that most precious farm commodity: peace of mind.

The stress lines on your face will go away as you invest in modern round bale wrapping technology today. What used to mean sleepless nights during haying season has become remarkably simple with today’s wrapping systems.

Contents

The Real Cost of Doing Nothing

Have you ever visited dozens of farms where the wrapping system paid for itself in just one season by preventing what would have been catastrophic losses? Farmer reports show that one dairy operation in Wisconsin calculated they saved nearly $18,000 in replacement feed costs. In favorable conditions, that’s before counting the improved milk production from higher quality feed.

So, let’s talk numbers any farmer will understand. A single spoiled bale can mean $50-75 straight off your bottom line, depending on bale size and feed value. Then, weather-related losses can wipe out up to 30% of your harvest in a bad year. It’s not over. What about the hidden cost of moldy feed that shows up in vet bills and poor herd performance?

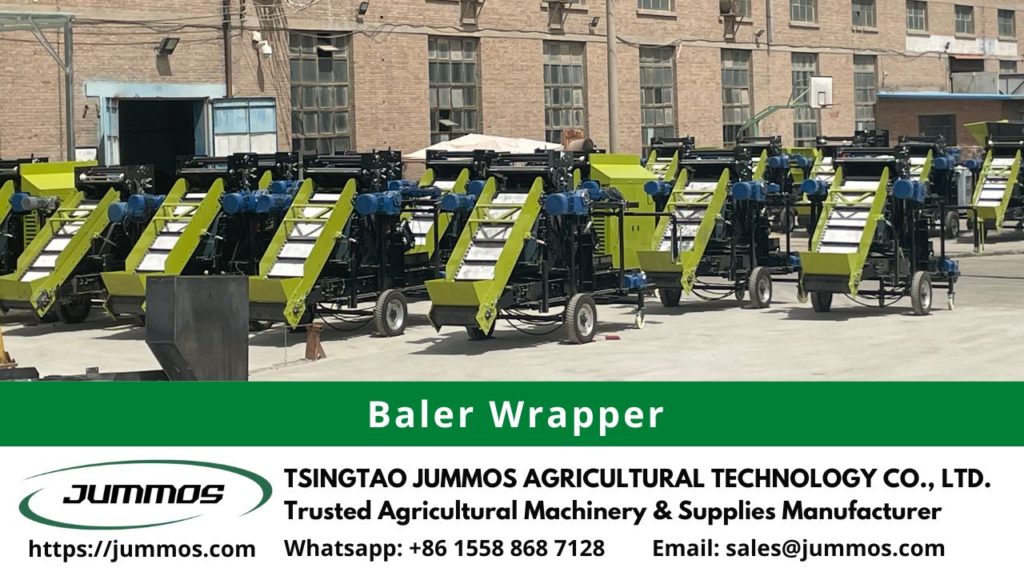

So, modern wrapping systems have come a long way from the early prototypes. Today’s round bale wrapping solutions offer precision wrapping that adapts to different bale sizes. Then, the UV-resistant films can withstand up to a full year outdoors in favorable conditions.

This system also has smart features that alert you to potential issues. It’s the great options that work for operations of any size.

The best part? The learning curve is surprisingly gentle. Farmer feedback shows most can become completely comfortable with the system after just a few uses. And the time saved on tarping, moving bales to storage, and dealing with spoilage more than makes up for any initial training period.

Why Smart Farmers are Making the Switch?

Many farmers have got the feed cost crisis. With feed representing 60-70% of livestock expenses, in many operations, every spoiled bale hits your bottom line twice. Farmer reports show they were spending nearly $20,000/year replacing ruined hay in Nebraska.

The USDA also reports roughly a 28% increase in weather-related feed losses since 2020. Summer’s drought ruined the pasture in Oregon, but their wrapped silage got them through. They have no choice to bring the round bale wrapping solutions in as the wrapping eliminates the backbreaking work of moving and tarping bales. In some cases, their crew in Colorado spends 75% less time on feed management now.

The real farm results in Wisconsin where the operation saw ROI in about 14 months. They can also cut the feed replacement costs by around 35%. In some trials, the wrapped bales maintained approximately 94% nutritional value after 10 months outdoors.

It’s simpler than you think. Modern systems have evolved far beyond early models. They have user-friendly controls even Grandpa can operate. Then, the mobile units can work where you need them.

The Science of Preservation

Round bale wrapping solutions work by creating the perfect environment for feed preservation through oxygen-free sealing that stops spoilage at its source. Moreover, there is a precision moisture control maintaining ideal 50-60% levels and multi-layer protection against UV rays and extreme weather. Actual performance may vary depending on forage type, storage conditions, and film quality.

You can also do the configurations customization for different crop types and storage durations.

Farmer observations and field trials indicate that operations implementing round bale wrapping solutions report transformative results:

Quality Assurance

It has up to 93%+ nutrient retention over 12-month periods in favorable conditions. Then, it will bring you consistent feed quality regardless of outdoor conditions. And the most important thing is the elimination of mold and waste issues.

Workflow Improvements

This is reported as 65% faster bale processing versus traditional methods. So, you will get simplified storage with no permanent structures required. When this is critical harvest periods, you can reduce labor demands.

Financial Impact Analysis

The economic advantages of round bale wrapping solutions become clear when examining direct savings and indirect benefits.

Direct Savings

It will have around 28-32% reduction in feed replacement costs according to farmer reports. Then, there will be approximately $15,000+ annual savings on average dairy operations. Surprisingly, it will show you up to 40% less required storage infrastructure.

Indirect Benefits

This solution will improve the herd health metrics. The herd will also get better feed conversion ratios. And of course, it will reduce weather-related risk exposure.

Implementation Best Practices

Success with round bale wrapping solutions depends on proper adoption. It has to be strategic planning and operational excellence.

Strategic Planning

At least, there are three things you can apply. Match the right-size equipment to current and future needs. Then, consider the seasonal workflow patterns. Don’t forget to account for local climate conditions too.

Operational Excellence

You must do the comprehensive staff training programs. Then, decide the preventive maintenance schedules. Last but not least, do the quality control checkpoints.

Final Note

So, from now on you have to calculate your current feed loss costs. Then, visit a neighboring farm using wrapping technology and also talk to your ag lender about financing options. You can start small if needed — even partial adoption has shown measurable benefits in some farms. The question isn’t whether you can afford to implement wrapping technology. It’s whether you can afford not to.