Industrial hemp is a versatile crop that comes with various potentials. The famous reputation of this crop is for recreational medication. Deeper than that, various industries could use that as material, especially for biomass energy and fiber production. The part that will play an important role for these purposes is the stalks. At this time, we will foreground the use of hemp stalks for industrial purposes including the application, wrapping and baling techniques, etc.

Contents

Industrial Hemp: Hemp Stalks as the Precious Materials

The cellulose contained in hemp stalks is known to be at a high level. This fact makes the fact of the plant worth more. For biomass production purposes, this part of the plant can be used after the harvesting process is completed. Besides, it works also for other purposes like fiber extract, etc. The ideal age for harvest is about 4 months of cultivation. And the height will reach 16 feet maximum. You also can feel that it is sturdy enough when reach the ideal time for harvesting.

The stalks at that time were in the form of cut crops. It is almost impossible to just bring it to the other places to do the next step. These scattered crops of stalks are first compacted by turning them into bales. The baking process usually uses a big machine to help the farmers. Doing this manually could take a long time, especially for large fields.

From Collection to Storage Solutions

The sequence of steps in baking is material collecting, then pressing it at once shaping it according to what you need. An advantage of baling is to expedite the material transportation and storage. The farmers or the helpers can just grab it with both hands or with a machine. There is no worry that the stalks will scatter.

To make it even easier to carry and store, you can add a rope, netwrap, or film wrap. Those three have their own advantages. The rope makes it easy to carry but it is still possible for the crop to scatter (but not much). The net wrap is safer but it still has the possibility of environmental disturbance.

The film wrap is the safest, but in case it is air-tight, the quality and the condition of the stalks must be maintained. However, the silver lining of all this is that wrapped bales can help in maximizing the space (no useless space because all will be used) and the efficiency of the storage increases. That is because it is more organized and doesn’t need special requirements for storage, unlike if you store it in the form of loose crops.

Unlocking Other Industrial Hemp’s Potentials

Fiber production is as popular as biomass energy production. It has special features, they are stronger than the other fiber and can be stored for a longer time. This fiber later can be used as construction materials, plastics (biodegradable version), paper, ropes and the most common thing made of fiber: textile. In the previous era, fiber was the material of sail canvas. The term ‘canvas’ was actually derived from the hemp’s scientific term ‘cannabis’. If anyone is an expert in linguistics, he or she will notice the relation between the words ‘canvas’ and ‘cannabis’.

Recently, hemp fiber products can be seen in various goods such as homewares, accessories, clothing, dog collars, shoes, etc. Hemp is as popular as it is because of its linen-like fiber. This material can become a second choice. Even it can be developed into a main material and be sought primarily. However, for now, people still believe in the first thing (as substitution or completion). It is mixed with other materials like lyocell for clothing.

Hemp Stalks Qualities

If you examine the products and materials closely, you’ll see that hemp stalks support eco-friendly goals with two key qualities. First, it offers sustainability as it’s a renewable natural resource that regrows quickly. Second, it’s eco-friendly, being safe for the environment and showing positive environmental responses to its cultivation.

Hemp requires significantly fewer pesticides compared to other plants that struggle to survive among animals and weeds. Pesticide use is rare, only necessary during severe pest infestations. Hemp naturally suppresses weed growth, eliminating the need for herbicides and reducing reliance on chemical interventions. Additionally, hemp improves soil health, acting as a reclamation agent that restores fertility.

During cultivation, hemp helps prevent soil erosion, reinforcing the soil and protecting it from losing vital substances in the rain. It also removes heavy metals and toxins from the soil, safeguarding it against harmful substances.

Moving from soil benefits to construction, hemp serves as an effective insulation material. Its lightweight nature adds minimal weight to buildings, and its non-toxic property alleviates health concerns. Hemp excels in heat absorption, outperforming some types of wood, and it also acts as an efficient sound barrier.

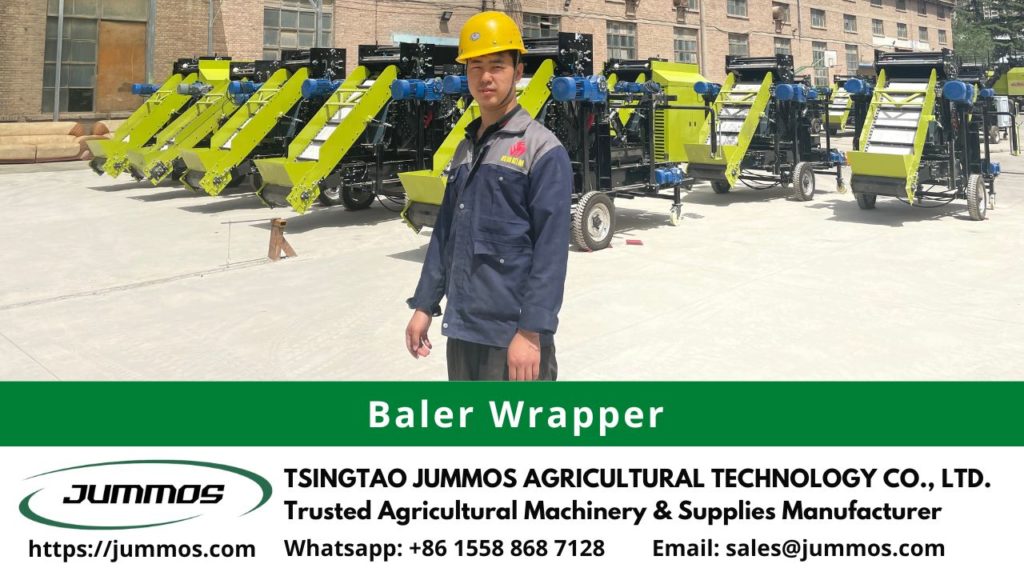

Baling Industrial Hemp with Modern Machine

Industry purposes always require a constant and fast cycle. Time becomes so much more important. Quantity also matters when something seriously becomes business. However, choosing the machine type and brand could be complicated. Otherwise, it could be super simple when you already know which one provides you the best.

Jummos is one of the brands that offer you a great deal. We provide high-quality baling and wrapping machines with the latest technology. Each machine is equipped with user-friendly operation. If you are new to this machine, with simple learning, you will easily master it. Bale your industrial hemp with Jummos machines, and be one step ahead.